Advancements in Electromechanical Motor Technology

Electromechanical motors are fundamental components in various industries, driving the machinery and devices that form the backbone of modern life. These motors convert electrical energy into mechanical motion, enabling many applications, from industrial automation to household appliances. Understanding the role and importance of electromechanical motors in an electro mechanical company can help us appreciate the advancements that continue to enhance their performance and efficiency.

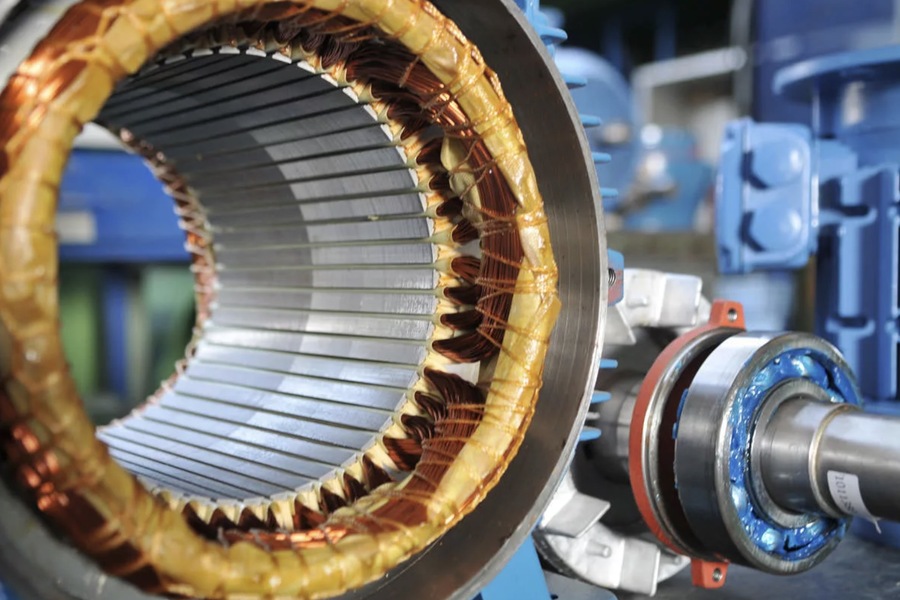

An electromechanical motor typically consists of several basic components: a stator, rotor, bearings, windings, and a commutator or brushless design, depending on the motor type. The stator generates a magnetic field, the rotor turns within this field, and the bearings support the rotor’s rotation. Windings create the magnetic field, and the commutator or electronic controls manage the direction of the current flow, ensuring smooth operation.

Page Content

Recent Innovations in Motor Efficiency

The push for higher energy efficiency has led to significant advancements in electromechanical motor technology. Energy efficiency is crucial for reducing operational costs and minimizing environmental impact. Innovations in materials and design have been at the forefront of this progress.

New materials such as advanced magnetic composites and rare-earth elements have significantly improved motor efficiency. These materials reduce energy losses due to heat and magnetic resistance. For example, using neodymium magnets in brushless DC motors has resulted in higher efficiency and better performance.

Design innovations, such as optimized rotor and stator geometries, have also contributed to energy savings. These designs minimize air gaps and reduce losses associated with magnetic flux leakage. According to a report by the International Energy Agency, these advancements could lead to a 20% reduction in energy consumption across various applications.

Durability Enhancements

Increasing the durability and lifespan of electromechanical motors is essential for reducing maintenance costs and downtime. Advances in materials science and cooling technologies have significantly enhanced motor durability.

Wear-resistant materials, such as advanced ceramics and composite coatings, have been developed to withstand the harsh operating conditions of industrial environments. These materials reduce wear and tear on critical components, extending the motor’s operational life. For instance, the use of silicon carbide in bearing and sealing components has improved wear resistance and thermal stability.

Cooling technologies have also seen remarkable improvements. Enhanced cooling systems, such as liquid and advanced air cooling designs, efficiently dissipate heat generated during operation. These cooling systems prevent overheating, a major cause of motor failure. Studies have shown that motors with advanced cooling technologies can operate at higher power densities without compromising reliability.

Integration of Smart Sensors

Integrating smart sensors into electromechanical motors has revolutionized monitoring and maintaining these devices. Smart sensors collect a wide range of data, including temperature, vibration, speed, and load. This data is crucial for predictive maintenance and performance optimization.

Predictive maintenance relies on real-time data to identify potential issues before they lead to motor failure. For example, vibration sensors can detect early signs of bearing wear, allowing for timely replacement before catastrophic failure occurs. Temperature sensors monitor operating temperatures to ensure the motor stays within safe limits, preventing overheating and subsequent damage.

The data collected by smart sensors is also used to optimize motor performance. Algorithms analyze the data to adjust operating parameters, ensuring the motor runs at peak efficiency under varying conditions. This adaptive approach enhances performance and extends the motor’s lifespan by preventing excessive wear.

Predictive Maintenance Technologies

Predictive maintenance technologies have profoundly impacted operational efficiency and cost reduction. By utilizing data from smart sensors, predictive maintenance systems can forecast potential failures and schedule maintenance activities accordingly.

Case studies have demonstrated the effectiveness of predictive maintenance in preventing downtime and extending motor operational lifespan. For instance, a U.S. Department of Energy study found that predictive maintenance reduced motor failures by 30% and extended the average motor lifespan by 25%. In another example, a manufacturing plant implemented predictive maintenance for its motor-driven systems, resulting in a 15% reduction in maintenance costs and a 20% increase in equipment uptime.

Advanced Control Systems

Advancements in motor control systems have further enhanced the operational capabilities of electromechanical motors. Adaptive control and variable frequency drives (VFDs) are key technologies that improve motor performance and efficiency.

Adaptive control systems continuously adjust motor operating parameters based on real-time conditions. This dynamic adjustment ensures optimal performance and energy efficiency. For example, adaptive control can modulate motor speed and torque in variable load applications to match the load requirements, minimizing energy consumption.

Variable frequency drives (VFDs) allow precise motor speed and torque control. By varying the frequency and voltage supplied to the motor, VFDs optimize performance for different operating conditions. This capability is particularly beneficial in applications with varying load demands, such as HVAC systems and conveyor belts. VFDs have been shown to reduce energy consumption by up to 40% in certain applications.

IoT and Connectivity

The Internet of Things (IoT) has significantly advanced motor technology. IoT enables connectivity and communication between motors and enterprise systems, facilitating remote monitoring and management.

IoT-connected motors can transmit real-time data to centralized monitoring systems for continuous performance tracking and analysis. This connectivity enables proactive maintenance, as potential issues can be identified and addressed before they lead to failure. Additionally, IoT integration supports automated reporting and analytics, providing valuable insights into motor performance and operational efficiency.

In industrial settings, IoT-connected motors are integrated with enterprise resource planning (ERP) systems and manufacturing execution systems (MES). This integration streamlines operations, improves resource allocation, and enhances overall productivity. For example, a manufacturing facility using IoT-connected motors reported a 15% increase in production efficiency and a 10% reduction in energy consumption.

Applications in Key Industries

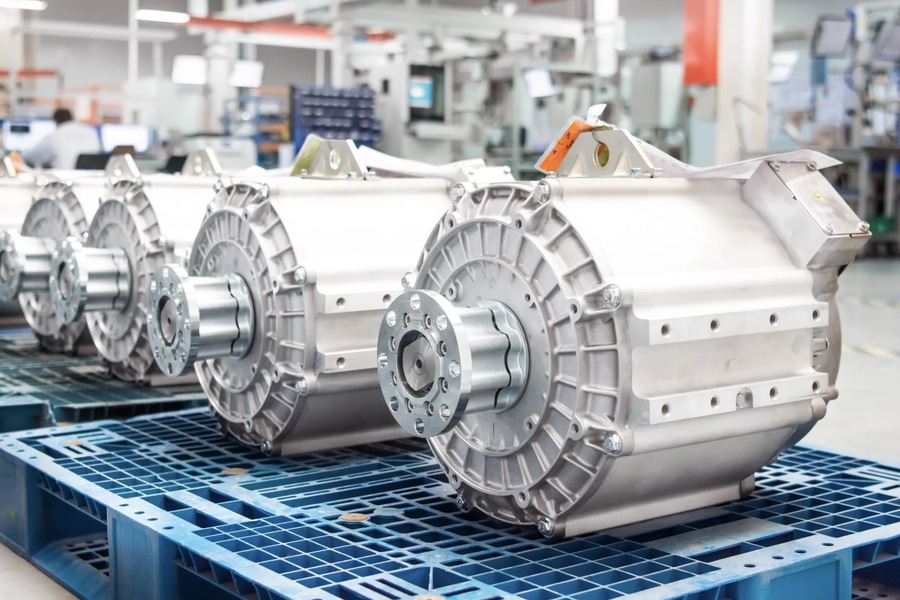

The technological advancements in electromechanical motors are significantly impacting various industries. These advancements benefit key sectors, including manufacturing, automotive, and renewable energy.

In manufacturing, advanced motor technologies improve production efficiency and reduce operational costs. High-efficiency motors and predictive maintenance systems enhance reliability and minimize downtime, increasing productivity. For example, a study by the International Federation of Robotics highlighted that advanced motor technologies contributed to a 10% increase in manufacturing output and a 5% reduction in energy consumption.

The automotive industry is also witnessing substantial benefits from advanced motor technologies. Electric and hybrid vehicles rely on high-performance motors for propulsion. Motor efficiency and durability innovations have increased vehicle range and reduced maintenance requirements. According to a report by the Electric Power Research Institute, advancements in motor technology have extended the average range of electric vehicles by 15%.

Electromechanical motors play a crucial role in wind turbines and solar tracking systems in the renewable energy sector. High-efficiency motors improve the energy conversion process, maximizing power output from renewable sources. A National Renewable Energy Laboratory study found that advanced motor technologies increased wind turbine efficiency by 8%, contributing to higher energy yields.

Future Trends in Motor Technology

The future of electromechanical motor technology looks promising, with ongoing research and development focused on further enhancements. Emerging trends include developing new materials, advanced manufacturing techniques, and innovative control methodologies.

Research into new materials, such as high-temperature superconductors and advanced composites, can revolutionize motor design. These materials could significantly reduce energy losses and improve overall efficiency. Additionally, advancements in additive manufacturing (3D printing) enable the production of complex motor components with higher precision and lower costs.

Innovative control methodologies, such as artificial intelligence and machine learning, are being explored to optimize motor performance. AI algorithms can analyze vast amounts of data to predict optimal operating conditions and identify potential issues before they occur. This proactive approach enhances reliability and extends motor lifespan.

Conclusion

The advancements in electromechanical motor technology are driving significant improvements in efficiency, durability, and performance. From new materials and designs to smart sensors and predictive maintenance, these innovations are transforming the industry. Integrating IoT and advanced control systems further enhances operational capabilities, providing valuable insights and optimizing performance.

As these technologies continue to evolve, industries such as manufacturing, automotive, and renewable energy stand to benefit immensely. Keeping pace with these advancements is crucial for maintaining competitiveness and achieving sustainable growth. The future of electromechanical motors is bright, with ongoing research promising even greater innovations that will shape the industry for years to come.